SERVICES

Construction

First and foremost, ICT Industrial is an industrial construction contractor providing project management, craft labor, procurement, and subcontractor management services to Owners, EPC/EPCM, and General Contractors across the industrial sector.

ICT Industrial’s management and project personnel bring decades of experience combined with ICT Industrial’s Vertically Integrated Project Delivery methodology to provide improved project value to its clients, while executing work with industry leading safety, and quality.

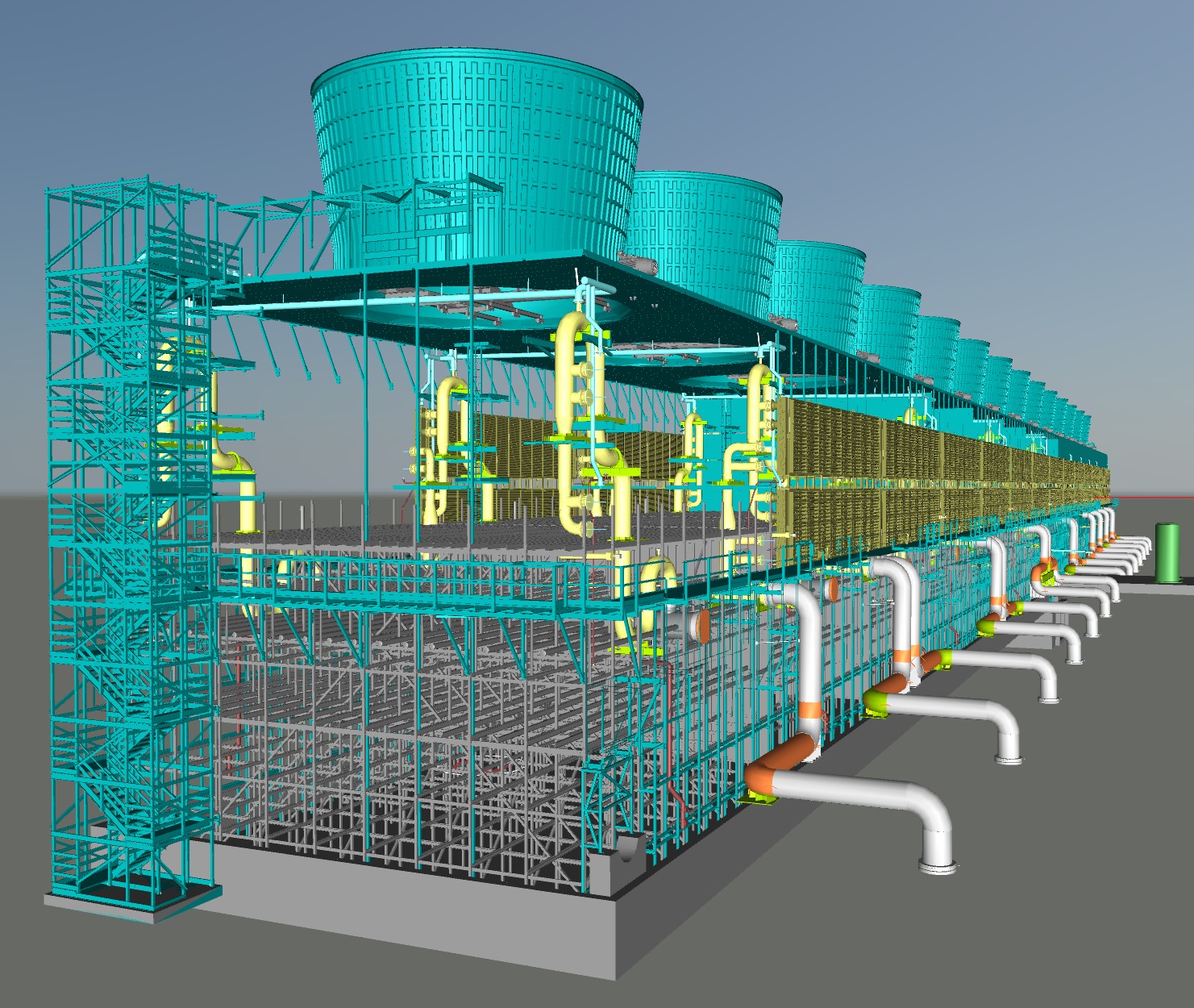

Throughout its history, International Cooling Tower has endeavored to be a one stop shop for everything related to wet cooling: design, supply, fabrication, construction, maintenance, and decommissioning/replacement. ICT Industrial continues on this established tradition, self-performing as many aspects of project delivery so as to provide maximum value to clients. By minimizing the need for discipline focused contractors, ICT Industrial can remove both compounding markups/margins, while also reducing overall project risks associated with the management of additional interface points.

ICT Industrial is able to self-perform the majority of field construction work including, but not limited to:

- Scaffolding

- Concrete Construction

- Wood-frame Construction

- Steel Erection

- Equipment Installation (Static & Rotating)

- Module Installation

- Pipe Erection

Other disciplines of work such as heavy earthworks, electrical, instrumentation, and insulation is evaluated on a project-by-project basis to determine how to maximize the value of the work. This can include self-performance of the work, maximizing local project content through the use of regional/local or indigenous contractors, and/or forming a joint venture with a partner who specializes in the required disciplines of work.

EPC Services

Although construction focused, ICT Industrial has continued the work of its predecessor to maintain the ability and expertise to execute EPC projects for its clients. Maintaining a focus on innovation in its applied design philosophy and procurement strategies to build upon the similar approach used in its construction methodology, ICT Industrial is able to provide additional value to its clients through lowered Total Installed Cost (TIC), improved reliability, lower cost of ownership, improved constructability, and a design for maintainability philosophy.

Pre-Construction

Whether paired with or without EPC services, ICT Industrial is able to provide significant improvements in client value through the execution of industry leading and best practices associated with Pre-Construction activities. ICT Industrial offers Constructability, Value Engineering, and Workface Planning services, during the FEED and detailed design stages of project execution.

Constructability focuses attention on the potential impacts, benefits, and risks to construction execution associated with proposed design philosophies and details. Optimizing fabrication, pre-assembly & modularization, facility layout, and project schedule can provide significant improvements to project total cost, schedule, quality, and overall success.

Continuing this philosophy into Value Engineering ensures ICT Industrial’s clients maximize their value and return over the life of their facilities. This can include the integration of new emergent & efficient technologies, reduction of parasitic power through the application of alternative hardware/software, creation of secondary markets for waste materials, or the reduction in operating costs through non-traditional applications of renewable power and water treatment technologies.

Workface Planning begins during detailed design and continues up until the execution of construction activities. The application of Workface Planning Best Practices has been shown to reduce costs, improve productivity, minimize waste, and improve construction schedules. Extending the project’s work breakdown structure (WBS) down to further detail provides a way to manage resources, track progress, and report results in a meaningful fashion which allows for successive improvements to project execution.

Fabrication

ICT Industrial and its affiliates provide specialty fabrication services, both as stand-alone services and as part of integrated full-service offerings coordinated to maximize value and return for its clients. By including fabrication in our Vertically Integrated Project Delivery methodology, ICT Industrial is able to eliminate additional interfaces during project integration while ensuring alignment of technical and construction resources. Traditionally, vendor representatives and construction contractors would have only limited communications during execution which can lead to delays or rework.

ICT Fabricators in Chandler, Arizona provides custom FRP structure and miscellaneous steel fabrication services for all industries. FRP is a corrosion resistant material ideal for both wet/humid and caustic/acidic environments where traditional steel structures are subject to high corrosion rates.

ICT Deltak in Minneapolis, Minnesota is a North American and global leader in the design, fabrication, and installation of gas fired heat recovery equipment.

In addition, ICT Industrial works with its established international network of third-party fabricators and vendors to provide its clients with best value options for materials or items ICT Industrial does not produce itself. Process piping spools, ductwork, and fabricated structural steel structures are just a few of the items ICT Industrial can supply as part of its network of strategic relationships.

FRP Structure & Piping

International Cooling Tower has developed a high level of expertise in fibre-reinforced plastic (FRP) structures and piping as a result of the evolution of cooling tower designs from wood to FRP components.

ICT Industrial has continued to further develop and expand this FRP knowledge, understanding, and service offerings over the past 6 years to become uniquely positioned as an FRP construction specialty services provider for industrial applications. ICT Industrial is pleased to offer a variety of FRP services to its clients, including but not limited to:

- FRP Fabrication – Process Pipe & Structure

- FRP Structural Design

- FRP Pipe Installation & Field Wrapping (Jointing)

- FRP Structural Erection

- FRP Application Evaluation & Cost Benefit Analysis

- Constructability

- Maintainability

- Material Suitability & Selection

- Specialty FRP/GRP Strategic Sourcing & Procurement

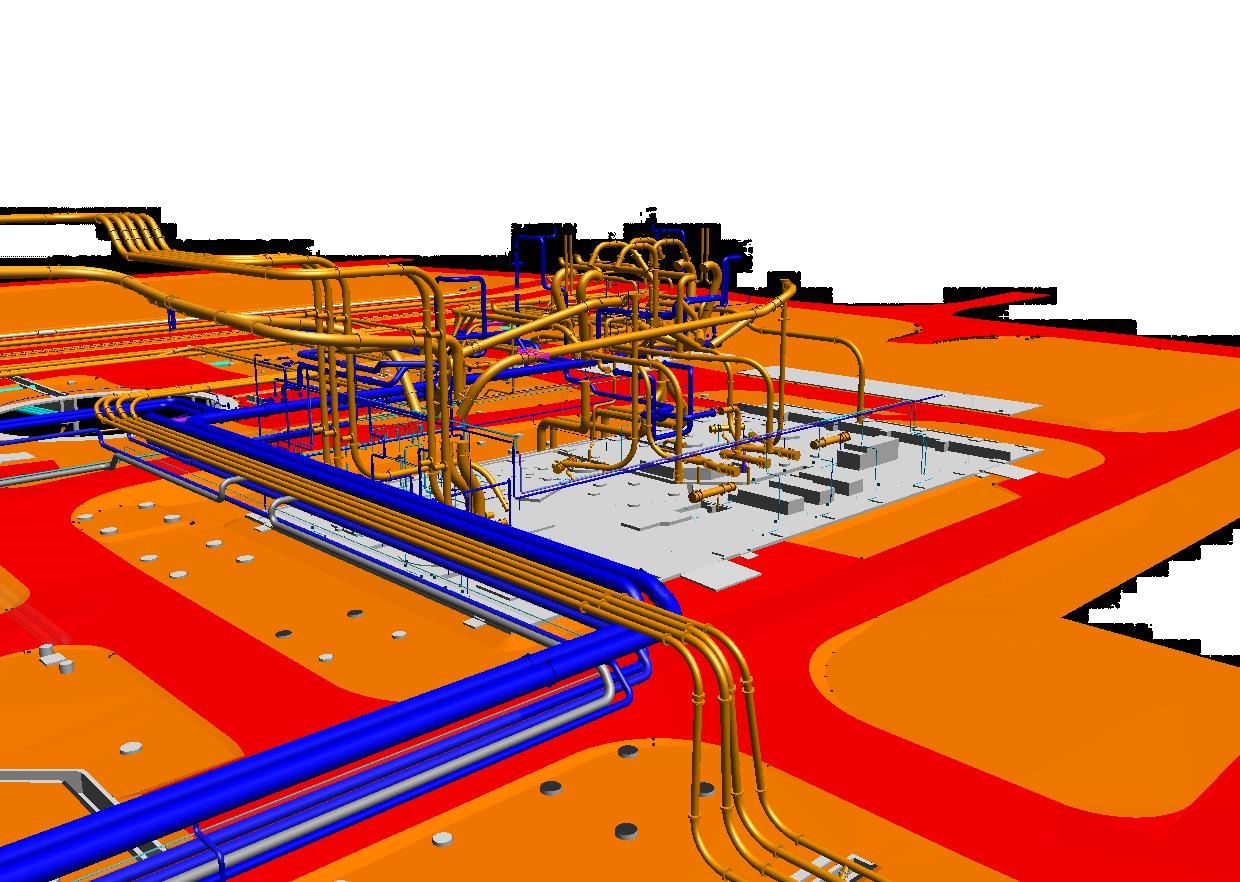

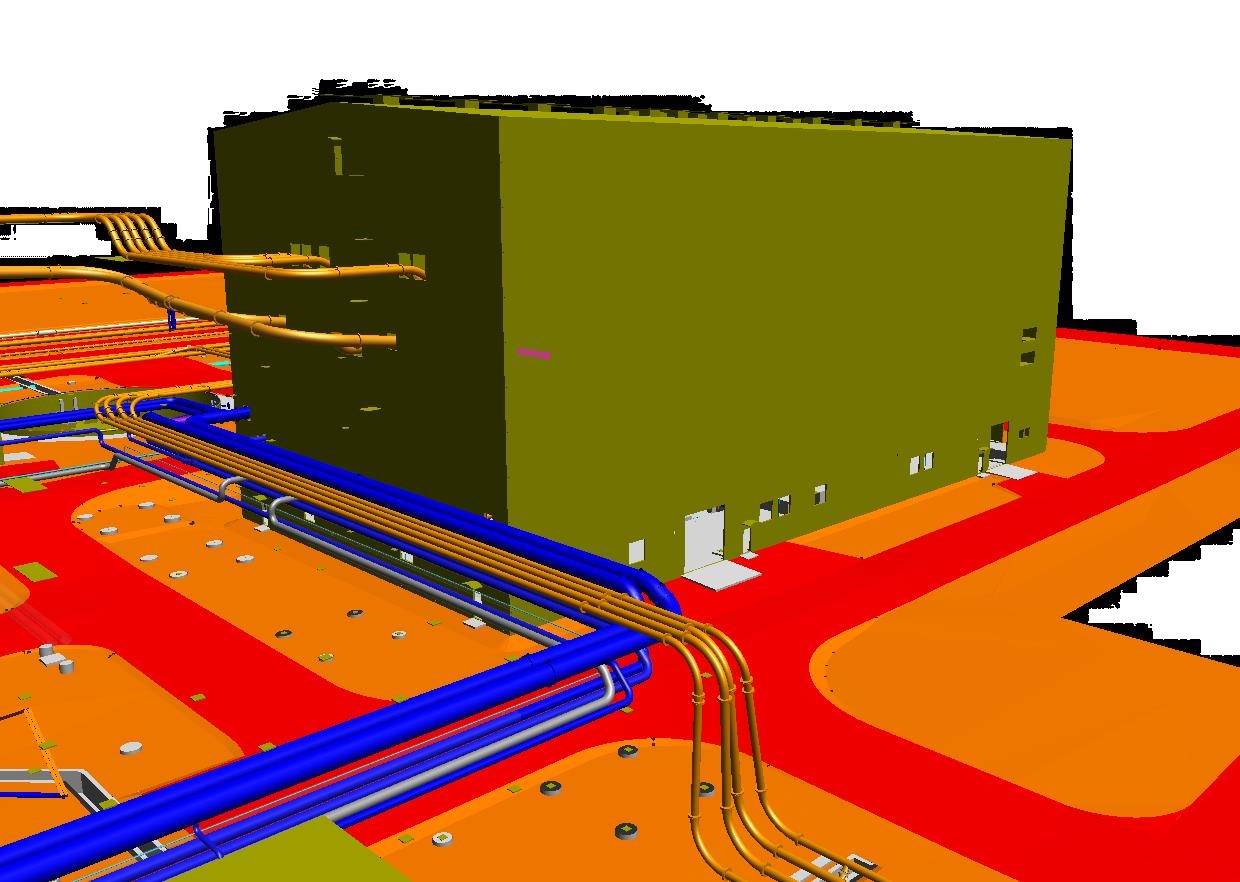

Modularization

Beginning in the Western Canadian Market in the early 2000’s, ICT Industrial’s construction professionals have been at the forefront as Modularization has grown from a niche service for industrial plant construction into an international best practice in facility design. Employing modularization as a strategy assists Owners in overcoming and/or mitigating a number of construction challenges, such as schedule constraints, worker availability, and logistical limitations.

Designing for Modularization can improve project performance in areas of safety, quality, and productivity. Through detailed planning and transitioning of work scopes to more controlled, manufacturing-type environments, ICT Industrial is able to minimize at-risk conditions, improve the overall quality of workmanship, therefore reducing rework, and improving the overall efficiency of the work.

Over the past 12 years ICT Industrial’s personnel have overseen the production of over 1,500 oversized process and pipework modules, and continues to use modular construction methods in new applications such as the construction of cooling towers, air cooled condensers, and process plants.

Procurement

As a full-service design, supply, and fabrication original equipment manufacturer (OEM), International Cooling Tower has established a complete network of both domestic and international suppliers for all manner of materials required for industrial cooling projects. ICT Industrial has leveraged and expanded on this capability to most effectively source all materials required to support and execute its industrial construction projects. Being able to fully execute project procurement internally and integrate this capacity with ICT Industrial’s EPC, Pre-Construction, Fabrication, and Construction knowledge, creates another avenue for improving the value and efficiency of ICT Industrial’s project execution.

Commissioning

& Start Up

ICT Industrial’s Vertically Integrated Project Delivery model continues beyond construction completion to provide unified commissioning and start-up services.

Turnover from construction is unified with documentation from equipment/material suppliers, other contractors, and the project engineers to ensure clients receive a clear and concise package of technical information. Doing so minimizes the hurdle to successful startup caused by discrepancies in the information available to the parties involved.

ICT Industrial’s services include craft labor, supervision, quality management, and project management personnel to support commissioning and start-up working under the direction of a client’s start-up and/or operations personnel. Integration with clients as a single service provider ensures priorities and work activities are aligned and completed in a sequence which continues to maximize the value and meet the ongoing project objectives for the successful and on-time operation of the facility.